Philosophie

Quality awareness, sustainability, customer orientation and team spirit: This is what BTS Turbo stands for.

About usEnvironment & Energy

We want to set an example in our industry in terms of sustainability and environmental awareness.

Our actionsQuality

For full satisfaction of ours, the quality of our products is constantly checked and improved.

Our claimWe are Turbo

BTS GmbH was established in 2004 under the umbrella of the Bauer Group of Companies as a third pillar alongside the Engines, Machinery and Technology divisions. In April 2012, the sister company BTS Turbo GmbH in Austria was added.

The claim that BTS sets for itself has been lived in the Bauer Group for more than 60 years: We want to implement the wishes of our customers quickly and flexibly with the highest quality requirements. Topics such as sustainable management, modern, environmentally friendly production methods and energy efficiency are indispensable maxims for our entrepreneurial activities.

The latest technologies are used within the Bauer Group: In the area of remanufacturing, for example, BTS benefits from the high professional-industrial standard in the production process as well as from state-of-the-art machinery. The Bauer Group also relies on the latest technologies in areas such as IT and communication, thus creating an optimal working environment for the parts trade at BTS.

The claim that BTS sets for itself has been lived in the Bauer Group for more than 60 years: We want to implement the wishes of our customers quickly and flexibly with the highest quality requirements. Topics such as sustainable management, modern, environmentally friendly production methods and energy efficiency are indispensable maxims for our entrepreneurial activities.

The latest technologies are used within the Bauer Group: In the area of remanufacturing, for example, BTS benefits from the high professional-industrial standard in the production process as well as from state-of-the-art machinery. The Bauer Group also relies on the latest technologies in areas such as IT and communication, thus creating an optimal working environment for the parts trade at BTS.

Environment & Energy

Energy efficiency – economical use of resources

The goal of BTS Turbo is to keep the impact on the environment as low as possible in all activities and to contribute to the solution of regional and global environmental problems with our own possibilities. We take responsibility for future generations and our region.

Annual certification of our environmental management system to ISO 14001:2004 and our energy management system to ISO 50001:2011 is carried out by Dekra Certification GmbH.

Our principles:

The goal of BTS Turbo is to keep the impact on the environment as low as possible in all activities and to contribute to the solution of regional and global environmental problems with our own possibilities. We take responsibility for future generations and our region.

Annual certification of our environmental management system to ISO 14001:2004 and our energy management system to ISO 50001:2011 is carried out by Dekra Certification GmbH.

Our principles:

- Our guiding principle in all our actions is to avoid or reduce to a minimum any environmental impact, even beyond the legal requirements, through a continuous improvement process. This includes constant checks to see whether auxiliary materials and processes with a lower environmental impact can be used, as well as the adaptation of technical equipment and development.

- Greater material efficiency is to be achieved by reducing the use of materials, such as by reducing scrap, reducing waste, or increasing the use of replacement parts.

- Recycling and disposal is important and is implemented at the Bauer Group of Companies.

- Responsibility for environmental protection is the responsibility of every single employee in the company.

- It is the particular task of management to create the conditions for ensuring that the safety of people and the protectiRegular maintenance of machinery and equipment, immediate rectification of defects and monitoring of the effectiveness of environmental protection measures are carried out at Motoren Bauer.

German Raw Materials Efficiency Award

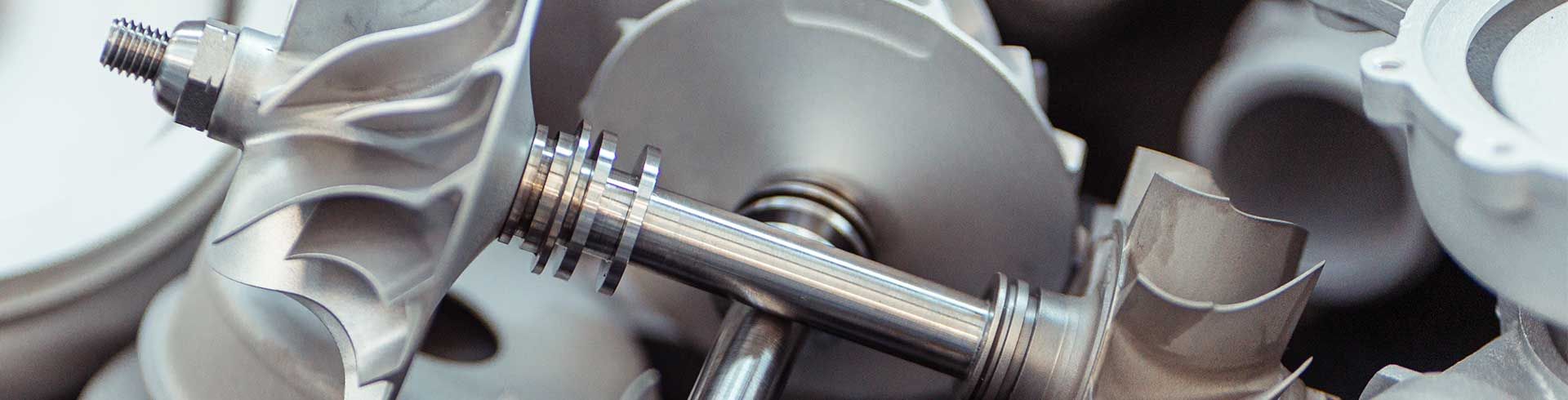

BTS Reman program

Our turbochargers from internal combustion engines are collected through a deposit system. They are then specifically reconditioned, repaired or recycled. This not only saves materials through reuse, but also avoids emissions in the production process.

For this program (then known as the Blue Turbo program), we were awarded the 2017 German Raw Material Efficiency Prize by the German Federal Ministry for Economic Affairs and Energy.

Our turbochargers from internal combustion engines are collected through a deposit system. They are then specifically reconditioned, repaired or recycled. This not only saves materials through reuse, but also avoids emissions in the production process.

For this program (then known as the Blue Turbo program), we were awarded the 2017 German Raw Material Efficiency Prize by the German Federal Ministry for Economic Affairs and Energy.

Quality

Quality is a question of details

The high quality standards of our products and services ensure not only our competitiveness, but above all that of our customers. BTS GmbH is committed to high quality and industry standards. To meet these high requirements, BTS undergoes annual certification according to ISO 9001:2015 by ALL-CERT Gesellschaft für Zertifizierungen mbH.

Of course, our customers are the focus of our work. The benchmark for quality is determined by you: We meet your expectations with competence and reliability. We see the high quality standard of our products and services as the most important basis for a long-term development of our company.

We work growth-oriented and constantly expand or improve our scope of services as well as the quality of our products and services. With these we want to occupy a high position in our market segment and rank among the best suppliers. A comprehensive quality management system integrated into all business processes ensures mastered process flows.

The high quality standards of our products and services ensure not only our competitiveness, but above all that of our customers. BTS GmbH is committed to high quality and industry standards. To meet these high requirements, BTS undergoes annual certification according to ISO 9001:2015 by ALL-CERT Gesellschaft für Zertifizierungen mbH.

Of course, our customers are the focus of our work. The benchmark for quality is determined by you: We meet your expectations with competence and reliability. We see the high quality standard of our products and services as the most important basis for a long-term development of our company.

We work growth-oriented and constantly expand or improve our scope of services as well as the quality of our products and services. With these we want to occupy a high position in our market segment and rank among the best suppliers. A comprehensive quality management system integrated into all business processes ensures mastered process flows.